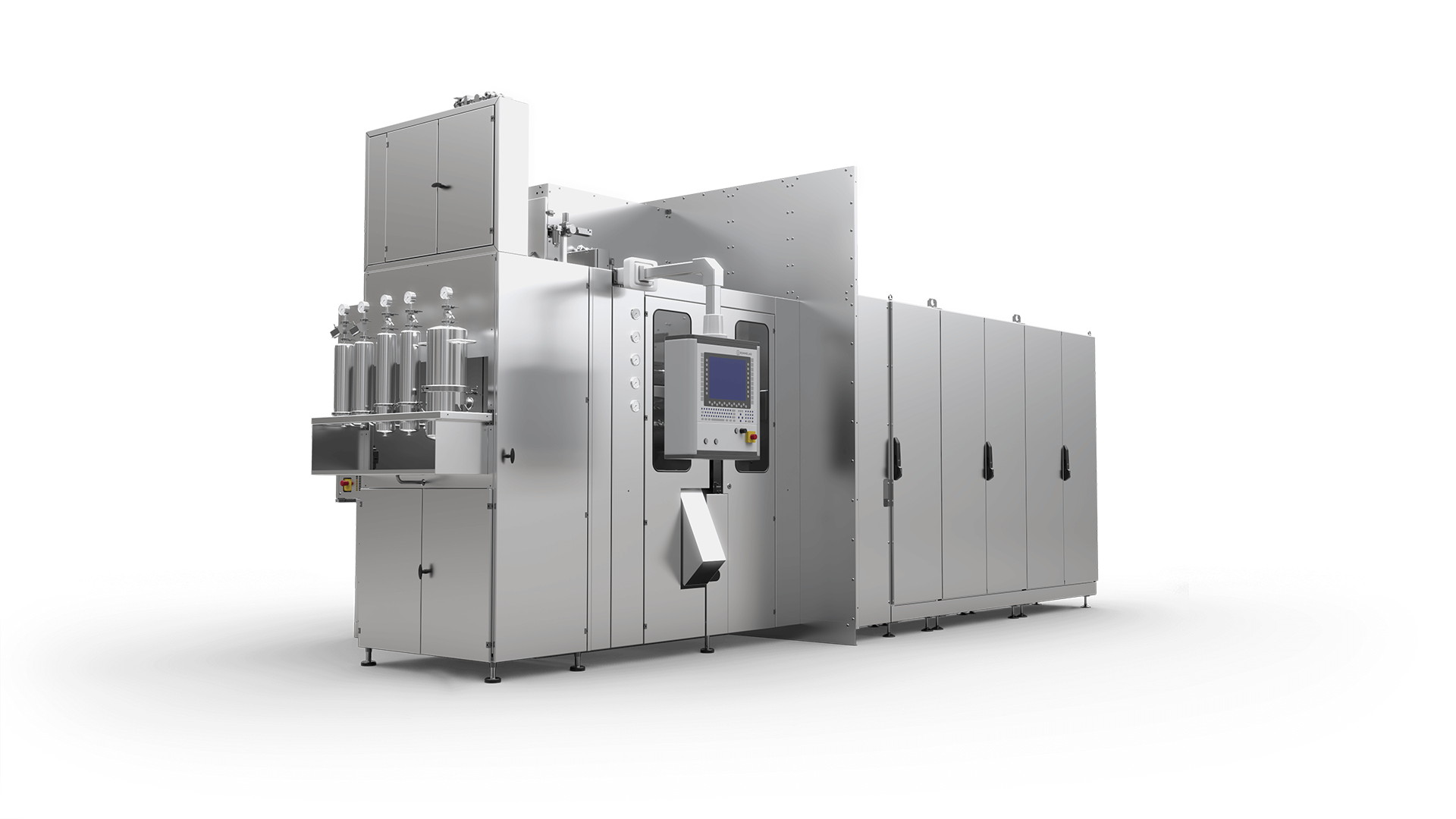

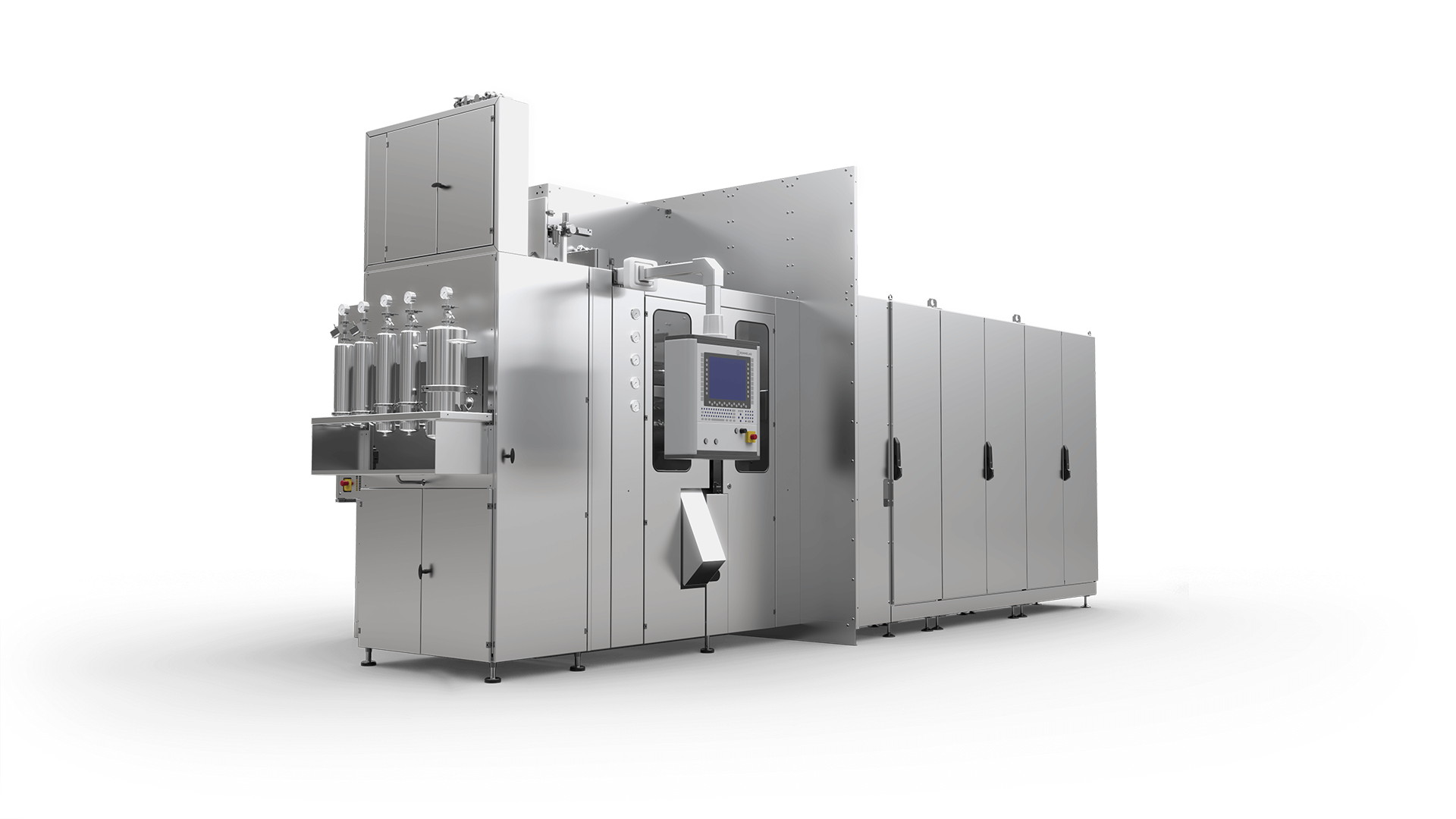

bp 321M

| Output: | Up to 9,000 pcs/h |

| Filling volume: | 0,1 – 50 ml |

| Ampoule length up to 208 mm | |

| Ophthalmic, Inhalations, Injection, technical products |

Our aseptic filling machines leverage our Blow-Fill-Seal (BFS) technology to deliver unparalleled production speed, reliability, and sustainability for ampoules and bottles. Capable of producing up to 33,000 BFS containers per hour, our compact bottelpack machines save valuable cleanroom space while helping you stay ahead in competitive pharmaceutical, healthcare, and biotech markets.

Benefits

By processing cost-effective polymer granulate, our aseptic filling machines can produce up to 33,000 containers per hour in nearly any shape. This high throughput, combined with reduced operating costs, translates into exceptionally low unit costs.

Our compact filling machines minimize investment costs for cleanroom facilities and filtration systems. In addition, bottelpack systems eliminate the need for space allocated to empty container storage, cleaning, or sterilization processes.

All product-contacting lines are automatically cleaned, sterilized, and dried with sterile-filtered air.

For over 60 years, Rommelag’s Swiss precision and German engineering have earned bottelpack machines a reputation for reliability. Many of our aseptic filling systems have been operating continuously for decades—a testament to their longevity and a key reason why we’re a leading aseptic filling machine manufacturer worldwide.

Thanks to modular design and the flexibility of the latest bottelpack generation, you can adapt your filling volume in just 15 minutes and perform a complete format change in under two hours—helping you stay ahead in dynamic markets.

We take big steps towards more sustainable production with each new machine generation. Our latest machines generate 80% less production waste, consume 75% less energy, and save 420,000 liters of water annually.

Machine Portfolio

Ideal for smaller filling volumes, our aseptic ampoule filling machines create securely sealed ampoules suitable for various applications, including ophthalmics, inhalation solutions, and injectables. They can produce up to 33,300 ampoules per hour at filling volumes ranging from 0.1 to 50ml.

| Output: | Up to 9,000 pcs/h |

| Filling volume: | 0,1 – 50 ml |

| Ampoule length up to 208 mm | |

| Ophthalmic, Inhalations, Injection, technical products |

| Output: | Up to 18,000 pcs/h |

| Filling volume: | 0,1 – 50 ml |

| Ampoule length up to 208 mm | |

| Ophthalmic, Inhalations, Injection |

| Output: | Up to 11,250 pcs/h |

| Filling volume: | 0,1 – 30 ml |

| Closed parison and ampoule length up to 127 mm | |

| Ophthalmic, Inhalations, Injection |

| Output: | Up to 29,000 pcs/h |

| Filling volume: | 0,1 – 30 ml |

| Closed parison and ampoule length up to 92 mm | |

| Ophthalmic, Inhalations, Injection |

| Output: | Up to 33,300 pcs/h |

| Filling volume: | 0,1 – 20 ml |

| Closed parison and ampoule length up to 68 mm | |

| Ophthalmic, Inhalations, Injection |

| Output: | Up to 25,000 pcs/h |

| Filling volume: | 3 – 60 ml |

| Closed parison and ampoule length up to 130 mm | |

| Ophthalmic, Inhalations, Injection |

| Output: | Up to 12,960 pcs/h |

| Filling volume: | 0,1 – 20 ml |

| Closed parison and ampoule length up to 130 mm | |

| Ophthalmic, Inhalations, Injection |

| Output: | Up to 21,600 pcs/h |

| Filling volume: | 0,1 – 20 ml |

| Closed parison and ampoule length up to 130 mm | |

| Ophthalmic, Inhalations, Injection |

For larger volumes, such as infusion solutions and wound irrigation products, our aseptic bottle-filling machines produce up to 10,000 bottles per hour, with filling volumes ranging from 50 to 2,000 ml.

| Output: | Up to 3,300 pcs/h |

| Filling volume: | 50 – 2.000 ml |

| Bottles up to 303 mm | |

| Infusions, Wound Irrigation Solutions, Injection |

| Output: | Up to 4,000 pcs/h |

| Filling volume: | 50 – 2.000 ml |

| Bottles up to 303 mm | |

| Infusions, Wound Irrigation Solutions, Injection |

| Output: | Up to 6,600 pcs/h |

| Filling volume: | 50 – 2.000 ml |

| Bottles up to 303 mm | |

| Infusions, Wound Irrigation Solutions, Injection |

| Output: | Up to 10,000 pcs/h |

| Filling volume: | 50 – 2.000 ml |

| Bottles up to 303 mm | |

| Infusions, Wound Irrigation Solutions, Injection |

Reasons for Rommelag

We produce nearly all components in-house, guaranteeing consistent quality standards and minimizing supply chain disruptions. This vertical integration ensures on-time delivery and reliable support.

Our aseptic filling machines comply with the pharmaceutical industry's stringent requirements, including Annex 1 of the EU-GMP guidelines, as well as those of various regulatory authorities such as the EMA, FDA, Anvisa, and Abrasp.

Our comprehensive after-sales services ensure that your bottelpack machine delivers excellent quality day after day and operates economically.

Given the extended lifecycle of our aseptic filling machines, we offer in-house modifications and upgrades to keep pace with new regulations and market demands.

We offer expertise in planning, expanding, reorganizing, or optimizing your BFS production using our bottelpack machines.

If you lack a GMP environment or additional space, our Pharma Suite is at your disposal. Here, we handle production on your behalf using a bottelpack aseptic filling machine in a certified environment, ensuring top-tier quality and compliance.

Digitalization

Looking for real-time monitoring, intelligent documentation, and actionable insights to improve decision-making in your filling processes? Our suite of digital products and services enhances each bottelpack machine, driving continuous optimization and a decisive competitive edge.