With our digital products, gain complete visibility into your production data, allowing you to optimize processes based on solid facts rather than assumptions.

Digital Products and Services for bottelpack Machines

With the Rommelag Pharma Platform (RPP) serving as a reliable foundation within your machines, the Machine Hub acting as your central cloud-based portal, and coordinated automation working seamlessly in the background, we prepare your pharmaceutical production for the future. Our digital products empower data-driven decision-making, securing your competitive edge.

Benefits

Get Digital: For Good Reasons

Production outages are stressful, time-consuming, and costly. Our precise data visualization and analysis tools help you identify root causes and minimize downtime.

Use detailed information to accurately predict upcoming maintenance and avoid unnecessary downtime.

Pharmaceutical production is highly regulated, demanding extensive documentation. Our digitization and automation solutions reduce paperwork and streamline your processes.

Our RPP includes hardware data diodes that guarantee maximum security for your production. Simple disaster recovery also protects you effectively against data loss.

With an optimal digital foundation in our machines, modular expandability, and easy software updates, you're fully prepared for the future.

ROMMELAG PHARMA PLATFORM

Your Basis for Pharma 4.0

The Rommelag Pharma Platform (RPP) connects your bottelpack system with your shop floor network, office, and our service center, providing access to a detailed information model and extensive data utilization possibilities. Integration with third-party tools is also easily achievable.

Our hardware is specifically designed for production environments and includes integrated hardware data diodes, ensuring your production remains secure from external interference. External access occurs through a secure one-way cloud connection, and disaster recovery can be executed quickly without extensive IT knowledge.

Generic software modules allow for the deployment of identical versions across all Rommelag systems, increasing transparency and reducing the effort required for testing and qualification.

Machine Lifecycle

Digitalization Throughout the Entire Machine Lifecycle

Digital products

Unlock Data Access and Additional Services for Your bottelpack System

With our data analytics product, you can capture production data in real-time, recognize causes of failures, and optimize your processes based on actual machine data.

Archive and visualize your process data in the historian of your choice. Thanks to OPC UA and a comprehensive information model, you capture machine data securely with full data integrity.

Telemetric monitoring enables secure live monitoring and global data access for optimal, data-driven decisions—without compromising production integrity.

Monitor the key performance indicators (KPIs) of your bottelpack system to ensure you're meeting production targets and take immediate action if necessary. Additionally, track Overall Equipment Effectiveness (OEE) for long-term efficiency.

The digital spare parts catalog in our Machine Hub offers an overview of your bottelpack machines. You can view parts lists and order spare parts directly.

Added value for you

Development and Operations

Advantages

You can rely on it

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod.

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod.

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod.

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod.

Lorem ipsum dolor sit amet, consetetur sadipscing elitr, sed diam nonumy eirmod.

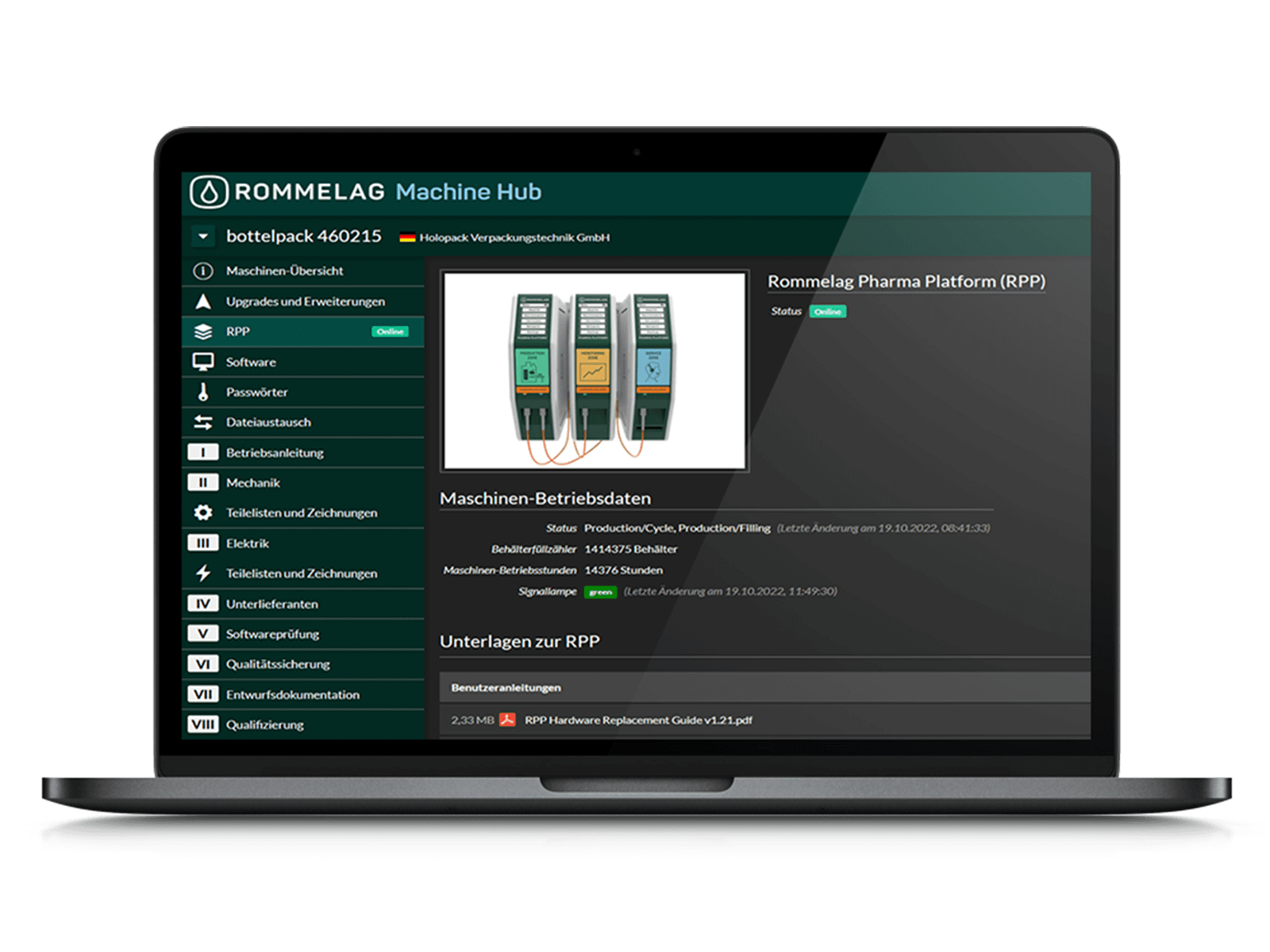

Machine Hub

Your Central Contact Point in the Cloud

With your bottelpack system, you gain access to the Rommelag Machine Hub, our comprehensive online tool. Easily view operating data for each machine, explore upgrades and expansions, and access all essential documents—from operating manuals and parts lists to technical drawings. You can also view software validations and securely exchange data with Rommelag.