Always ready for action: After-sales services for smooth BFS production

Even the best technology needs to be well-maintained. With our comprehensive after-sales services, you can ensure that your bottelpack system delivers outstanding quality and operates economically day after day. And if things do get stuck: Our experts are just a phone call away.

Successful start: Installation of your bottelpack system

Our mechanical engineering experts work tirelessly to ensure that your bottelpack system delivers top performance right from the start, from the precise setup to thorough testing and checking of all functions. Once everything is functioning smoothly, and the machine is optimally integrated into your plant or company's infrastructure, we hand over responsibility to you. If desired, our experts can also accompany you during production.

Know what works: Trainings

Of course, we instruct your employees step by step in all processes that are essential for a smooth production flow. Either in our training centre or at your site. In addition, we offer operator, technology and service training for process optimization - optionally at basic, advanced or expert levels. To this end, and with plenty of insight, we maintain two fully production-ready training machines. And because people like to look up concentrated knowledge, extensive documentation is available - in print and digital form. Full service.

Download the service agreement

Efficiency-enhancing: Rommelag Service Agreements

Our bottelpack lines are designed for long service. With regular, preventive maintenance, you make a significant contribution to further enhancing their service life and cost-effectiveness. Our service contract concept offers everything you need. Choose from modular services according to your needs: from inspection to reactive, from preventive maintenance to full-service solutions.

Better to look ahead!

Most of the time, everything goes as it should. However, if a machine shutdown does occur, it will cost you a lot of money. A professional machine inspection minimizes this risk, is less expensive and increases machine availability - and thus your productivity.

Our machine inspectors conscientiously carry out all maintenance work for you. In the case of cycle machines, for example, they also take over the maintenance of the fire alarm system.

Digital troubleshooting

If there is a problem, our experts will be there quickly. But they don't have actually to be on-site for every problem. Some things can be easily fixed remotely. This can save you valuable time and money. All we need is an Internet connection to the machine, which you can enable for us if required.

On the spot in time: Spare and wear parts packages

Using Rommelag's original parts also helps minimize machine downtime and increase your overall equipment effectiveness (OEE). We offer the entire range of parts from a single source - with the quality and availability that only the equipment manufacturer can guarantee. Our service experts will help you identify the correct parts and send them on time before maintenance.

Almost brand new: Overhaul and modernization

You can rely on us for the best quality and the highest level of vertical integration. This means that we install the highest quality components that do not have to be completely replaced if the worst comes to the worst. Rather, we can often refurbish them at a lower cost. Of course, every overhaul is carried out in accordance with the applicable rules of technology, so that at the end you practically have a plant in mint condition - no matter from which year of construction.

Would you like to be a little more up to date? Then we modernize our bottelpack system and add new functions if necessary. This increases your performance and maximizes process and result quality.

When it comes down to it: Repairs

Production processes are demanding, especially for technology. That is why the highest quality counts. We design and build all our bottelpack machines ourselves and therefore know each of them like the back of our hand. So when it comes down to it, we can provide spare parts at the best possible time - worldwide - thanks to our high vertical range of manufacture. As well as the necessary skilled workers. So that everything runs efficiently again in no time at all. Count on it!

Always available: Stocking and spare parts

Having the most important parts always on hand saves valuable time in the event of an emergency. Our service sales experts will be happy to advise you and optimize your spare parts inventory to fit your individual solutions. As a customer, you can also log into our Machine Hub with your ID and select from the spare parts catalog:

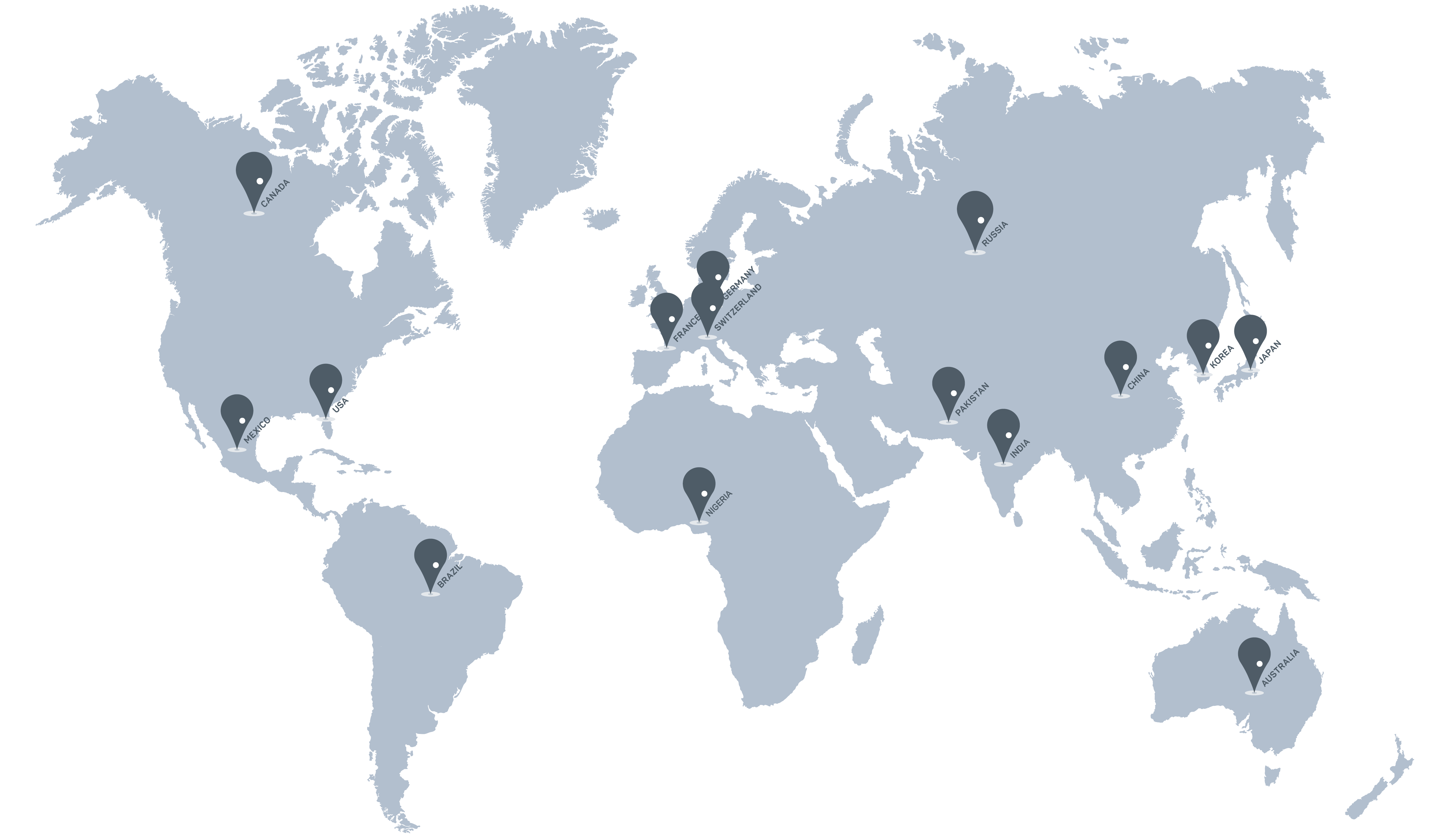

We’re there for you worldwide: Rommelag service network

No matter from where you contact us: Our service teams are close to you. In order to be able to support you optimally and quickly on site, we train them regularly in our manufacturing plants so that the teams have the necessary specialist knowledge when required. Call for support: on the phone, by e-mail or in person on site.

Arrange training appointment

Please let us know on which topic we may train you. We will contact you as soon as possible to arrange the place and time.

What kind of service would you like?

Please fill out the form completely. We will get back to you as soon as possible to discuss your request.

What kind of service would you like?

Please fill out the form completely. We will get back to you as soon as possible to discuss your request.

What kind of service would you like?

Please fill out the form completely. We will get back to you as soon as possible to discuss your request.

What kind of service would you like?

Please fill out the form completely. We will get back to you as soon as possible to discuss your request.

What kind of service would you like?

Please fill out the form completely. We will get back to you as soon as possible to discuss your request.

Send us your request

Thank you for contacting us. How can we help you?

The perfect solution for your application

Tell us your challenge. We will advise you in detail about the possibilities and find the optimal solution.